.png?width=900&name=RP%20America%20Green%203D%20Printing%20(1).png)

XYZprinting’s SLS machines can reduce waste and enhance efficiency, making additive manufacturing greener and more cost-effective.

3D printing provides incredible value in terms of innovation, speed, communication, and customization. These advantages are compelling enough to outweigh its downsides, such as high cost, high electrical demand, and the production of both hazardous and non-hazardous waste products. As technology evolves, however, companies gain the ability to mitigate these downsides.

Less Material Waste

SLS technology reduces waste with reusable thermoplastic resins. Depending on the platform you select, however, recycling this material can be challenging. Some SLS machines have material recycling efficiencies as high as 80/20 (a 20% refresh rate for un-sintered powder), while others require fresh powder at a rate of 50%. Those that require more fresh powder tend to be large-format machines that print larger parts. Whether hazardous or not, end-of-life powder waste presents a significant issue for machine owners, especially those who work with multiple machines.

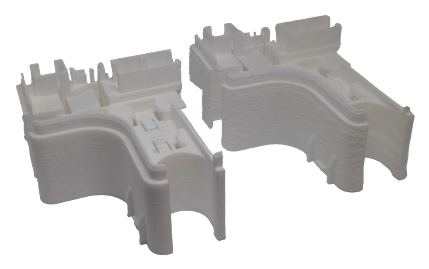

Left : EOS PA2200 end-of-life powder refreshed with 30% fresh XYZprinting powder (printed on the XYZprinting MfgPro230 xS)

Right : 100% EOS PA2200 end-of-life powder showing poor sidewall quality.

Despite the advantages SLS 3D printing provides over other manufacturing technologies, many of these machines can be wasteful. In the case of MJF 3D printing, polyamide and other SLS powders essentially liquify and flow from the energy of the laser or thermal system. Service bureaus and businesses with more than five large-format SLS and/or MJF machines face a storage dilemma as the wasted powder stacks up. How much do they have to pay for disposal, and what will the environmental impact be?

While the powder not being sintered or fused doesn’t melt or flow, it is subjected to damaging heat. The longer heat cycles required for larger builds cause more damage and waste. Typically, these voluminous builds require a higher ratio of fresh powder. As a result, waste is higher with large-format SLS machines.

Quicker Printing and Cooling Times

Smaller build volume SLS machines print and cool down much more quickly—up to 10 times faster than their large-format counterparts. This speed benefit is twofold: parts become available every 24 hours, and waste is significantly diminished, reducing overall print costs.

This is a significant and counterintuitive fact of using large-format SLS or MJF machines for serial part production. Many would naturally assume a big machine with a large build volume is most efficient for production. In reality, a small build volume SLS is typically faster, provides much faster cooling, and is more efficient in reducing waste.

Lower Cost

If improving efficiency and reducing waste isn’t enough, the price of XYZprinting’s MfgPro230 xS platform is about 20% of that of large-format SLS or MJF 3D printers. Machine redundancy and material choice flexibility are also significant advantages of adopting multiple small SLS machines.

Material Flexibility

In addition to producing more waste, most larger machines have a locked material system. This means the user can’t change parameters so they can buy material from a company other than the machine’s manufacturer. Few of these manufacturers make their own powder, and they all buy from the same patent-protected powder manufacturing companies. The more they sell, the more buying power they have with the powder supplier. This starts a vicious cycle that leads to more powder waste ending up in landfills.

XYZprinting has a different approach. They leverage high-performance, smaller build volume SLS machines that print high-quality parts and produce less waste, using an affordable, open-platform system. The open platform allows users to decide which powder they want to use and purchase it from any material supplier.

XYZ’s MfgPro230 can utilize material from a range of suppliers like PBT material from AM Polymers.

Another key benefit of the open-platform system is that users can fine-tune the heat variables in SLS printing. These parameters can be preset to allow operators to use powder that other SLS and MJF systems deem to be waste and produce accurate, high-quality parts in the XYZprinting SLS platform with no significant difference in mechanical properties.

Efficient Recycling

Consider a large 3D printing service bureau with an array of large SLS machines running concurrently. The service provider would likely have drums of waste powder waiting to be disposed of. Again, the cost of disposal and overall wastefulness is not trivial.

Much of this product has been damaged during the heating cycle and can no longer produce viable parts. The user is unable to make parameter changes and utilize the leftover material. Due to longer cycle processes, the powder from many SLS machines is even more damaged than that of the MJF machines; MJF machines have an optical sensor that reads the color of the powder and rejects it when it becomes slightly discolored. While it will no longer work in an MJF machine due to slight coloration, the health of this powder is very good for use in an open-platform XYZprinting SLS machine. This is why world-class additive manufacturing operations have adopted XYZprinting’s SLS machines.

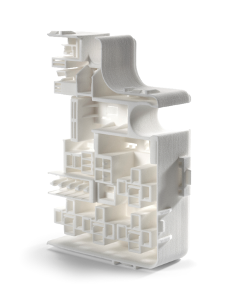

XYZprintiing’s MfgPro230 xS can utilize HP’s end-of-life powder mixed with EOS end-of-life powder to produce high-quality parts while eliminating costly waste.

As illustrated here, end-of-life or waste powder on a large-format SLS machine can be mixed with 20–30% fresh XYZprinting powder and get great results. One innovative solution for these multi-platform users is to mix the HP MJF PA-12 end-of-life powder with the end-of-life PA-12 powder from an EOS or 3D Systems machine.

XYZprinting machines can use this combination of PA-12 “waste product” to produce high-quality, low-cost parts while removing a big obstacle to the adoption of additive manufacturing.

RP America is a leading provider of industrial 3D printing equipment, software, maintenance, service, and materials. Visit our website to learn more about the XYZprinting MfgPro230 xS and MfgPro236 xS.

Topics: SLS

Older

Older