Part 2 of our Think Differently Series: Smart Design for Additive Manufacturing. Read part 1: How to Lightweight 3D Printed Parts here.

Additive manufacturing (AM) has been used for years as a way to quickly and inexpensively create prototypes during the product design process. This is still a widespread use of AM, but the technology has expanded into other uses as well, such as jigs and fixtures, casting patterns, injection molds, and other end-use parts. Every day, material and equipment developments bring us closer to using AM for mass customization and personalization of products on a large scale.

But why do people adopt AM in the first place, especially in a manufacturing environment in place of other processes?

Small number of components

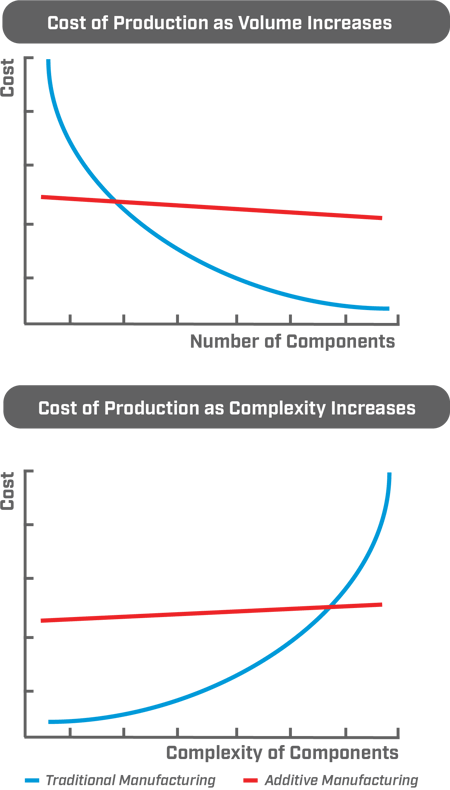

There are a couple reasons someone might choose to manufacture a part with AM rather than traditional subtractive manufacturing. The first has to do with the number of parts being produced. As the first graph depicts, in traditional manufacturing, as the volume of parts increases, your cost per part decreases drastically. In AM, the cost per part remains relatively stable no matter how many parts are produced. This means if you are manufacturing a very small number of parts—even just one, such as a prototype—AM may be a more cost-effective method.

Complex components

The other area where AM makes sense is in the production of complex geometries. As you can see in the second graph, in traditional manufacturing an increase in complexity leads to an exponential increase in the cost to produce.

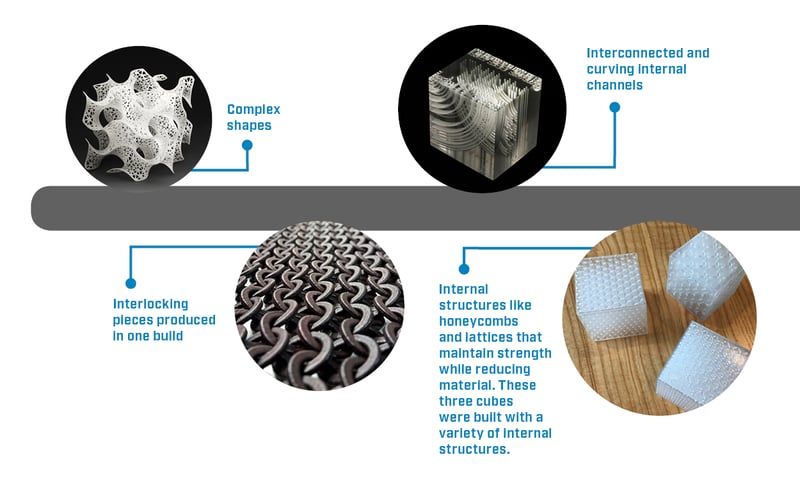

However, additive manufacturing remains relatively cost-effective as complexity increases. Not to mention AM allows designers to create complex geometries that are impossible in traditional subtractive manufacturing such as:

- Interconnected and curving internal channels

- Interlocking pieces produced in one build

- Internal structures like honeycombs and lattices that maintain strength while reducing material (a process known as lightweighting)

Integrating AM with smart design

It is easy to see in what situations AM might make sense. It can be harder for a company to figure out how to begin integrating AM at their operation. That's where smart design comes in. Designing for 3D printing isn’t just about learning a series of tips and tricks—it’s about totally changing your mindset as a designer. In our next post in this series, we'll discuss why we design the way we do traditionally, and how we can start thinking differently to avoid common pitfalls when designing for AM.

Topics: Smart Design for AM

Older

Older